Key benefits

- All racks can be custom made according to specifications.

- These containers are specially developed storage containers that are suitable for the storage and transport of different industrial components.

- They can be fitted one into other both in opened and closed state and in such manner the space utilization can be optimized.

- The containers can be handled by forklift and ensure that the elements are not damaged neither during the transport not the storage.

- KVJ pallets work well in automotive, foundry, military, manufacturing, clean room, pharmaceutical and heavy industrial applications.

- KVJ pallets can carry extremely heavy objects and are capable of withstanding rigors of tough environments.

- No splinters, that’s why metal works well in automated materials handling system.

- Various coating is applied to protect and improve the life of metal pallets. Options include: powder coats, wet painting, or galvanized coatings. Options:

- Powder coating

- Water-based paint

- Solvent paint

- Galvanizing

- Packing solutions can if required, be completed with plastic or wooden elements.

Vision, Strategy

-

Growth

KVJ’s primary focus is on organic growth through a more intense cultivation of established markets. Another important aspect of the growth strategy is also to follow multinational customers in their geographic expansions.

To strengthen the role as supplier of complete packaging solutions to selected market segments, the growth strategy includes co- operation with alliance partners, as well as acquisitions.

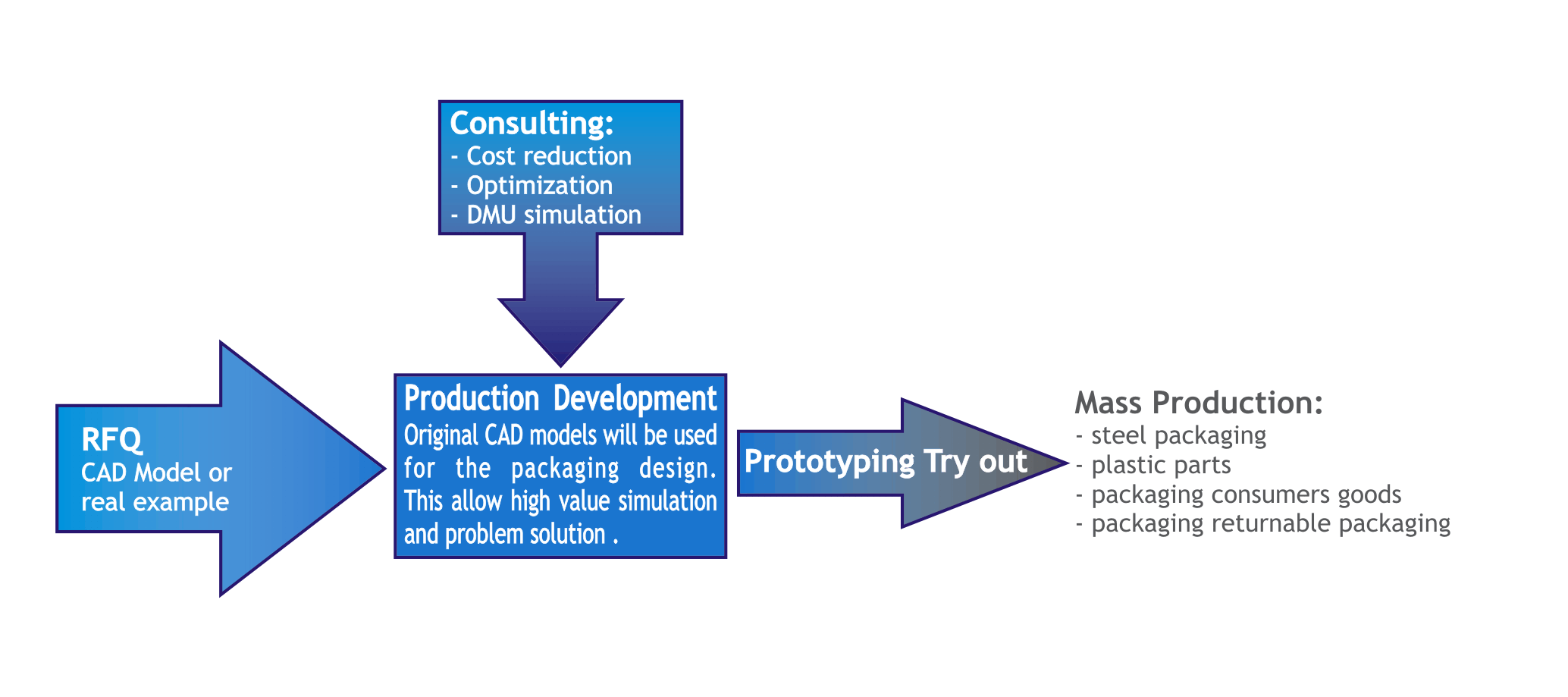

As part of the development process CAD-solutions offer a great opportunity to check the feasibility of a project by creating a virtual image of the expected solution. KVJ can provide you fully detailed designs for all your packaging needs.

The CAD data of the part will be read into our CAD system. These data will be used to optimize the positioning of the parts, critical distances and the ergonomically windows.

Result is a detailed virtual image of the packaging solutions.

The benefit of a digital master production model is that it helps to understand a product at an early design stage.

Prototyping & Production

Once the design has been perfected, and agreed a prototype will be built. These are made in our own die shop by our technicians using milling and turning machines. This affords us greater flexibility and ensures that deadlines are always met.

Manufacturing operations are continually striving for increased productivity. The goal is to satisfy the customer with exact product, quality, quantity and price int he shortest amount of time. KVJ production capacities cover all of needs.

Quality Management

-

ISO certification

As an ISO-9001 certified company, KVJ is continuously looking for improvements and higher quality standards.

ISO 9001:2000

ISO / TS 16949:2002

ISO 14001:2005

References

-

KVJ has many years of experience in the packaging system. Our references include virtually all the big names from industry.

-

Magyar Suzuki Corporation

design & serial production all special packaging systems

Mercedes-Benz A Class

design & serial production all special packaging

AUDI,

Volkswagen,

Ford,

MAN,

-

TIER1 suppliers:

Kirchoff Automotive, Tower Automotive, Futaba, Kayaba, Gedia, Tenneco Automotive, IAC Automotive, ZF Hungaria, Videoton Holding, Cascade Engineering Europe, ARRK, Loranger, Gestamp, Arvin-Meritor.